Graphite: A Comprehensive Overview

Introduction

Graphite, one of the most stable forms of carbon, is a naturally occurring mineral with a wide range of industrial applications due to its unique properties. It is widely known for its use in pencils, but graphite’s versatility extends far beyond that. With properties such as high thermal resistance, electrical conductivity, and lubricity, graphite is essential in industries like steel manufacturing, batteries, and even nuclear reactors.

This article delves into the mineral’s properties, formation processes, and how it fits into the broader context of mineral ore formation.

Physical and Chemical Properties of Graphite

Graphite has a distinctive crystalline structure and physical properties that are responsible for its broad applications.

1. Crystal Structure

Graphite is an allotrope of carbon where each carbon atom is bonded to three other carbon atoms in a hexagonal lattice. This results in sheets of graphene stacked upon one another, with weak Van der Waals forces holding them together. This sheet-like structure is the reason for many of graphite’s properties, such as its ability to act as a lubricant.

2. Hardness and Luster

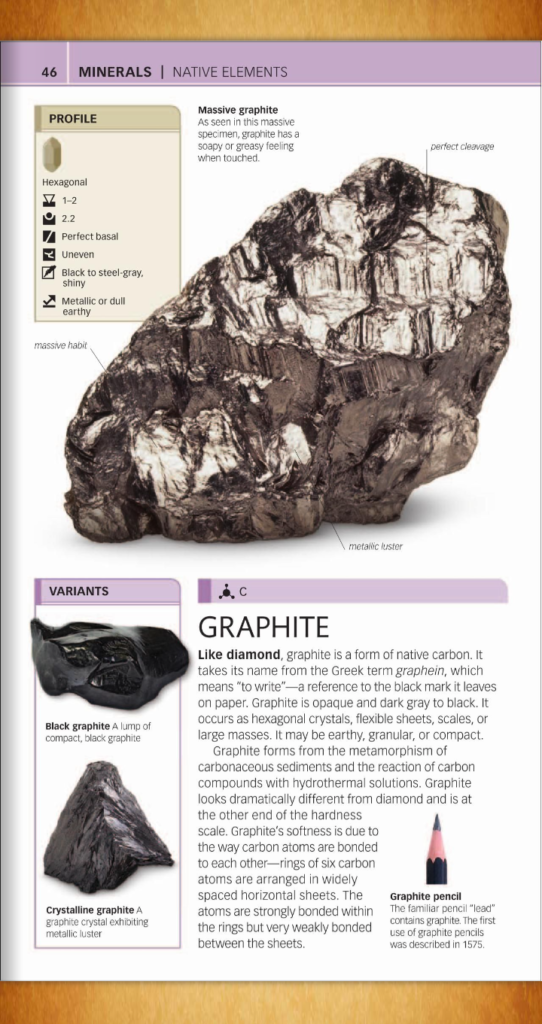

- Hardness: On the Mohs scale, graphite has a hardness of 1 to 2, meaning it is a very soft mineral.

- Luster: Graphite has a metallic luster and appears opaque in natural light.

3. Electrical and Thermal Conductivity

- Electrical Conductivity: Graphite is an excellent conductor of electricity, making it useful in applications like electrodes and batteries.

- Thermal Conductivity: It is also a good conductor of heat, and this property is utilized in high-temperature applications like crucibles.

4. Cleavage and Fracture

- Cleavage: Graphite has perfect basal cleavage, meaning it easily splits along its layers. This feature contributes to its lubricating properties.

- Fracture: When it fractures, graphite forms thin, flexible sheets.

5. Density and Specific Gravity

- Density: Graphite has a relatively low density compared to other minerals, with a specific gravity of 2.09–2.23.

Formation of Graphite

The formation of graphite can occur through various geological processes, depending on the environment and the source of carbon. The two main types of graphite deposits are crystalline (flake) and amorphous graphite.

1. Metamorphic Processes

Crystalline flake graphite is primarily formed through regional metamorphism. During the metamorphism of carbonaceous materials (such as organic-rich shales), high pressure and temperature cause carbon to crystallize into graphite. This process generally occurs in the presence of heat above 750°C and pressure exceeding 5 kilobars, typically in high-grade metamorphic rocks such as schists, gneisses, and marbles.

2. Hydrothermal Processes

Graphite can also form through hydrothermal activity, where hot fluids carrying dissolved carbon migrate through fractures in rock. These fluids precipitate carbon, which crystallizes into graphite veins. Vein graphite deposits, though less common, are some of the highest-grade sources of graphite.

3. Igneous Processes

Graphite can also form in igneous rocks, though this is rare. In such cases, it can crystallize directly from magma or during the cooling and solidification of carbon-rich magma intrusions.

Mineral Ore Formation and Occurrence

Graphite can be classified as a mineral ore, depending on its concentration and economic value in certain regions. Deposits of graphite are generally found in a variety of geological settings and can be exploited for industrial use.

1. Types of Graphite Deposits

- Crystalline Flake Graphite: Found in metamorphic rocks such as quartzite, schist, and marble. These deposits are typically associated with high-grade metamorphic terrains.

- Amorphous Graphite: This type of graphite forms from the metamorphism of coal seams. It has a lower carbon content and crystallinity compared to flake graphite.

- Vein (Lump) Graphite: This rare type of graphite forms in fissure veins and is known for its high purity and crystalline nature.

2. Major Graphite Deposits Worldwide

Some of the largest graphite deposits are found in:

- China: The largest producer of both amorphous and flake graphite.

- Brazil: Known for large deposits of high-quality flake graphite.

- India: Also a significant producer of flake graphite, mostly used domestically.

- Sri Lanka: Home to some of the world’s purest vein graphite.

Industrial Uses of Graphite

Graphite’s unique properties make it indispensable to various industries. Some of its most notable applications include:

1. Pencil Lead

Although synthetic graphite is now commonly used, natural graphite is still a key component in pencil lead, mixed with clay to control hardness.

2. Refractories and Foundry Crucibles

Due to its ability to withstand high temperatures without melting or reacting chemically, graphite is widely used in refractories, crucibles, and molds in the steel and metal industries.

3. Batteries

Graphite plays a critical role as an anode material in lithium-ion batteries, which power modern electronics and electric vehicles. Its excellent electrical conductivity and stability make it the preferred material for this purpose.

4. Lubricants

Because graphite flakes easily slide past one another due to their weak interlayer bonds, it is commonly used as a dry lubricant in high-temperature environments where oil-based lubricants cannot be used.

5. Nuclear Reactors

Graphite is used as a moderator in nuclear reactors to slow down neutrons during nuclear fission. Its high melting point and low neutron absorption cross-section make it ideal for this purpose.

Environmental Impact of Graphite Mining

While graphite is essential for many green technologies like electric vehicle batteries and renewable energy storage, its extraction has raised environmental concerns. Mining processes, especially for flake and amorphous graphite, can lead to habitat destruction, pollution, and the release of harmful chemicals into the environment if not properly managed. Thus, sustainability and responsible sourcing are critical in the graphite supply chain.

Conclusion

Graphite’s importance in modern technology and industry cannot be overstated. Its unique combination of properties—electrical conductivity, thermal resistance, lubricity, and more—ensures its continued relevance in industries ranging from steel production to electronics. As demand for green technologies rises, the future of graphite mining and processing will require innovation and environmental responsibility.

Understanding its geological formation and the factors that influence its occurrence helps us better appreciate this mineral and its impact on various sectors.

Would you like more details on any specific section, or do you have any questions to enhance the article further?